Metal sheet OEM/ODM services

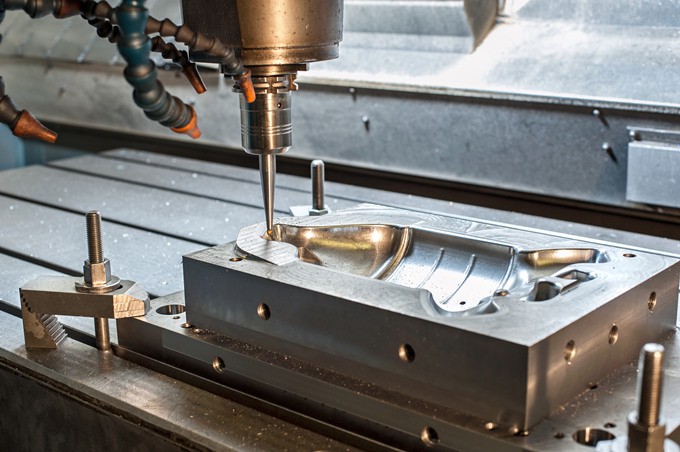

Yunfu Metal Forming Technology has a variety of stamping forming equipment for internal production and experienced engineers who can assess and design standard and progressive dies.

As a sheet metal supplier, we perform internal laser cutting, bending, welding, threading and chamfering, deburring, riveting, and other processes. We also have a complete supply chain for various surface treatments, giving us the capability to meet customers' needs for components and assemblies.

|

Materials |

||||

|

Aluminum |

5052 |

6061 |

6063 |

1060 |

|

Carbon Steel |

SPCC |

HRS |

SAPH440 |

|

|

Stainless Steel |

201 |

304 |

316 |

|

|

Galvanized Steel |

|

|

|

|

|

Thickness |

0.5mm |

1mm |

10mm |

20mm |

|

Equipment |

|

Mitsubishi CO2 Laser Cutting Machine 3kW |

|

LVD Fiber Laser Cutting Machine 8kW with Automatic Loading Tower |

|

AccurPress CNC Sheet Metal Bending Machine 100T-6 Axis |

|

LVD CNC Sheet Metal Bending Machine 80T-9 Axis |

|

LVD CNC Sheet Metal Bending Machine 80T-6 Axis |

|

LVD CNC Sheet Metal Bending Machine 24T-5 Axis |

|

Miller TIG, MIG, and Spot Welding Machines |

|

Panasonic TAW Welding Robot with 3-Axis Rotary Table |

|

Miller TIG, MIG, and Spot Welding Machines |

|

Panasonic TAW Welding Robot with 3-Axis Rotary Table |

|

CNC Sheet Metal Drilling and Tapping Machine |

|

Automatic Deburring Machine for Sheet Metal |

|

Secondary Processing |

|

TIG and MIG Welding |

|

Robotic Welding |

|

Spot Welding |

|

CNC Sheet Metal Bending |

|

Riveting |

|

PEM Insertion |

|

Laser Engraving |

|

Materials - Surface Treatment |

|

Powder Coating |

|

Anodizing |

|

Electrophoretic Coating |

|

Trivalent Zinc Plating |

|

Hot Dip Galvanizing |

|

Passivation |

|

Geomet |

|

Sandblasting |

Why choose Science Yunfu Metal Forming Technology for OEM metal processing services?

1,Science Yunfu Metal Forming Technology can assist you in making minor adjustments to your product design through Design for Manufacturability (DFM) to ensure that your parts can be produced accurately and efficiently, thus providing quality that meets your specifications.

2,We have the capability to manufacture complex and high-precision parts using steel, aluminum, and stainless steel.

3,Our ERP system enables us to manage internal manufacturing of finished products with multiple SKUs. To date, the most complex product we have manufactured consisted of 320 components.

4,We provide support for sheet metal products from design to manufacturing, all the way to large-scale production. We are capable of secondary operations such as welding, riveting, and surface treatment, and we can also provide sub-assembly services or deliver finished products.

5,The design and manufacture of manual and robotic welding fixtures are carried out by our in-house engineering team, ensuring the reproducibility of the manufacturing process.

We provide the best solution on request and provide timely service

Sheet Metal Fabrication: We offer custom sheet metal fabrication services for various materials, including steel, aluminum, and stainless steel. We have a range of machines and equipment for bending, shearing, stamping, and punching processes.

Secondary Operations: We provide secondary operation services, including welding, riveting, polishing, surface treatment, and more.

Design and Engineering: Our engineering team has years of experience and technical expertise to provide end-to-end solutions from product design to manufacturing.

Finished Product Fabrication: We offer finished product fabrication services, including packaging, assembly, and delivery.

Large-Scale Production: We have advanced equipment and processes to meet the demands of large-scale production while ensuring product quality and delivery time.

Supply Chain Management: We have a comprehensive supply chain management system to provide efficient and high-quality services to our customers, ensuring their needs are met.

Laser Cutting: We provide precision laser cutting and CNC bending manufacturing services.

Stamping and Forming: We provide stamping and progressive die services for medium to large-scale orders.

Assembly: We provide contract manufacturing services for product assembly.

Regenerate response

How to contact us

1.You can send an email to my email address, winner_sz@yeah.net, and we will not disclose any customer's privacy.

Tel: +8613915766588

Email: winner_sz@yeah.net

Add: Floor 1, No. 1, Lane 251, Fangde Road, Jiading District, Shanghai

2. Please leave your contact information and message, and we will contact you as soon as possible.